Prominent Features

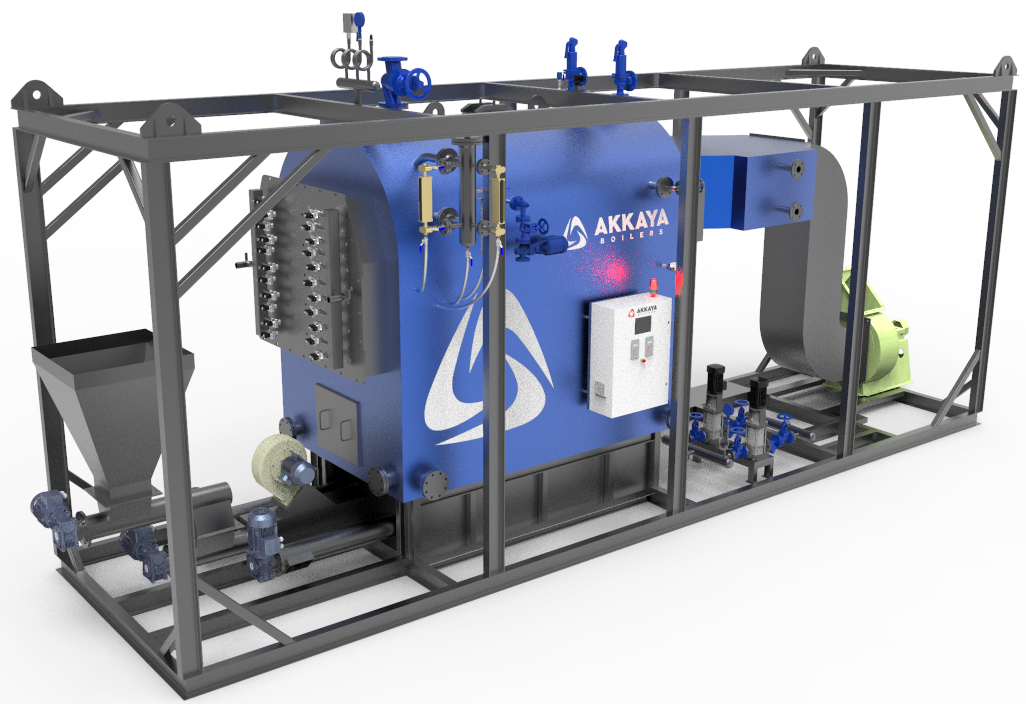

• Thanks to the package design, all equipment is assembled and the system is ready for use. In this way, it can be commissioned in a short time.

• Long service life specially designed for solid fuels such as biomass, coal and pellets; 2-stage, under feed stoker system and primary / secondary combustion air fans.

• Automatic fire extinguishing system with safety thermostat.

• Provides safe and stable operation thanks to high quality safety equipment.

• Thanks to PLC controlled touch screen control panel, quick technical support can be obtained from anywhere in the world with easy operation and remote access from mobile devices.

• Thanks to its design that provides fast steam generation, high quality steam generation is achieved in a short time and with high efficiency.

• Robust steel construction ensures easy handling and minimizes the risk of damage during shipment.

• Production in accordance with EN12953 and PED2014 / 68 CE directive

System Elements

• Akkaya High efficiency semi-cylindrical 3-pass steam boiler with 8 bar operating pressures

• Two-stage, under feed stoker system and fuel hopper consisting of long-life Cr-Ni alloy grille slices

• Grundfos brand feed water pump with valve, filter and check valves

• PLC based touch screen and remote access control panel

• Isolated feed water tank including level controller, water inlet solenoid valve assembly and level indicator

• Safety valves

• Water softening system

• 2 high quality electronic water level control systems

• Manometer and 3-way connection valve

• Reflex glass water level indicator

• Pressure switch

• Pressure transmitter

• Vacuum breaker and shut-off valve • Steam temperature sensor

• Flue temperature sensor

• High quality steam exit valve, water inlet valve and check valve

• Surface blowdown valve

• Bottom blowdown valve and bottom blowdown shut-off valve

• Concrete base, carrier chassis, wiring and piping between system equipment

Technical

| EBS SERIES SOLID / BIOMASS FUEL PACKAGED STEAM BOILER SYSTEMS | EBS 250 | EBS 375 | EBS 500 | EBS 625 | EBS 750 | EBS 1000 | EBS 1250 | EBS 1500 | EBS 1750 | EBS 2000 |

| Steam Generation Capacity (kg/h) | 250 | 375 | 500 | 625 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 |

| Operating pressure (bar g) | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Fuel Consumption / 4500 kcal / kg LHV – Max. 5% Moist, 5-50 mm | 42 | 63 | 83 | 104 | 125 | 167 | 208 | 250 | 292 | 333 |

| Stoker Dimensions | 650X600 | 650X600 | 650X600 | 650X600 | 650X600 | 650X830 | 650X830 | 650X830 | 650X840 | 650X830 |

| Thermal Capacity (kW) | 174 | 262 | 349 | 436 | 523 | 698 | 872 | 1047 | 1221 | 1395 |

| Electrical Connection Power 380V-3Phs-50Hz (kW) ** | 6,80 | 6,80 | 7,90 | 9,10 | 10,10 | 12,25 | 14,25 | 18,10 | 18,10 | 22,10 |

| Steam Outlet Connection (PN16) | DN32 | DN40 | DN50 | DN50 | DN50 | DN65 | DN65 | DN80 | DN80 | DN100 |

| Water Consumption @ 6 bar (kg/h) | 250 | 375 | 500 | 625 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 |

| Length (L) (mm) | 5800 | 5800 | 6100 | 6500 | 6850 | 7400 | 7850 | 7500 | 8100 | 8400 |

| Width (W) (mm) | 2200 | 2200 | 2200 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 |

| Height (H) (mm) * (All Accessories Assembled) | 2550 | 2800 | 2800 | 3050 | 3050 | 3150 | 3150 | 3550 | 3550 | 3550 |

| Weight (Kg) | 4200 | 4600 | 5100 | 6000 | 6300 | 7400 | 8200 | 9300 | 9600 | 9900 |

- Transport height can be reduced by approx. 200 mm by removing some accessories.

- ** According to the situation where all system motors are activated at the same time.

- Akkaya Inc reserves the right to make changes to the specifications.

Gallery