Prominent Features

• Semi-cylindrical type, 3-pass design with low flue gas temperatures and high efficiency.

• According to the type of fuel to be used in the boiler and customer request, suitable for use as a combustion system with the “Automatic Fuel Feeding Stoker“,”Water Cooled Vibrating Grate” and “Manual Grate” options.

• With appropriate combustion systems, wood, woodchips, charcoal, olive pomace, pellets, briquettes, almond husks, walnut husks, hazelnuts husks, pulps of fruit, seed husks, chicken manure and pellets, bamboo, corn cobs, forest scraps etc. many types of fuel can be used efficiently and with low emissions values. The fuel flexibility provided by the design of combustion systems keeps operating costs constantly low.

• Optional systems such as “Automatic Ash Removing System“,”Automatic Ignition System” and “Automatic Tube Cleaning System” that provide operator-free operation, allow efficient, stable and fully automatic controlled operation.

• The flue gas filter selected in accordance with the fuel characteristics (“Multicyclone“, “Cyclone“, “Wet Flue Filter“, “Bag Filter“) ensures that the emission values are kept below the permissible limits.

• There are service lids insulated with high temperature resistant concrete in sufficient number and suitable features for maintenance and service.

• Thanks to flue fan with frequency convertor, high heat resistance and v-belt drive, combustion and emission control is handled in a sensitive and safe way.

• The heating surfaces are clear and true values. The total area of heat transfer in the boiler is given clearly and accurately.

• Provides safe and stable operation thanks to high quality safety equipment.

• Thanks to PLC controlled touch screen control panel, quick technical support can be obtained from anywhere in the world with easy operation and remote access from mobile devices.

• Shipped with long-lasting insulation that minimizes heat losses.

• It is manufactured with furnace and firebox support lines and transmission shafts. The strength of the boiler and its resistance to thermal stresses are thus increased.

• Production in accordance with EN12953 and PED2014 / 68 CE directive

• Welding control of our boilers is carried out with ULTRASONIC test within the scope specified in EN 12953

• After the boiler tubes are fixed to the boiler mirror with roller expander, welding process is applied. Thus, the risk of cracks in welds due to thermal stresses occurring in boiler tubes is eliminated.

• Our welded productions are carried out by certified welders according to approved WPS and WPQRs. Automatic submerged arc welding, MIG-MAG and SMAW welding techniques are applied in accordance with the norms.

• They are manufactured by using high quality, certified boiler sheet and seamless boiler tubes in accordance with standard requirements.

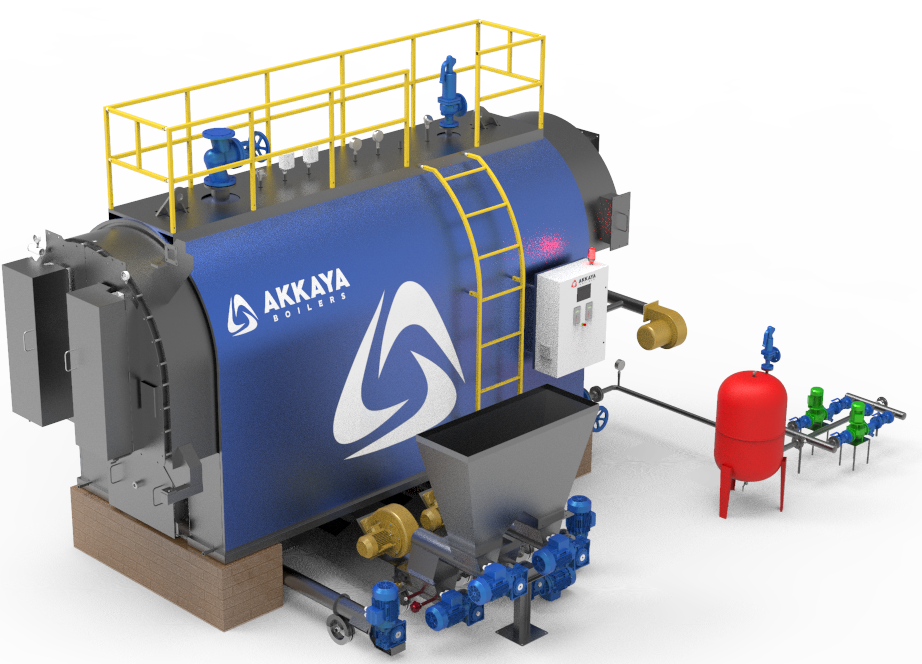

System Elements

• Akkaya high efficiency semi cylindrical, Scotch type 3 pass hot/superheated water boiler

• Combustion System (Automatic fuel feeding stoker, water cooled vibrating grate, manual grate)

• Boiler hot water flow/return valves

• Boiler filling and drain valves

• Boiler air valve

• Boiler thermometer

• PLC based touch screen and remote access control panel

• Safety valve

• Manometer and 3-way connection valve

• Pressure switch

• Pressure transmitter

• Boiler temperature sensor (operation)

• Boiler temperature switch (safety)

• Flue temperature sensor

• Flue gas filter (Multicyclone, cyclone, wet flue filter, bag filter)

• Flue fan with frequency convertor, high heat resistance and v-belt drive

• Automatic Ash Removing System, Automatic Ignition System, Automatic Tube Cleaning System, Circulation Pump Group, Expansion Tank, Fast Water Heating Tank, Accumulator Tank, Plate Heat Exchanger (Optional)

Techical Table

| YS SERIES SEMI-CYLINDRICAL TYPE HOT / SUPERHEATED WATER BOILERS | YS6 | YS8 | YS10 | YS15 | YS20 | YS25 | YS30 | YS40 | YS50 |

| Max. Working Pressure (bar g) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 100 | 10 |

| Total Heat Transfer Surface Area (m2) | 6 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| Max. Thermal Capacity (kW)** | 105 | 140 | 174 | 262 | 349 | 436 | 523 | 698 | 872 |

| Max. Thermal Capacity (kcal/h)** | 90.000 | 120.000 | 150.000 | 225.000 | 300.000 | 375.000 | 450.000 | 600.000 | 750.000 |

| Water Circulation Flow (m3/h)*** | 4,5 | 6,0 | 7,50 | 11,25 | 15,00 | 18,75 | 22,50 | 30,00 | 37,50 |

| Fuel Consumption (kg/h)** | 25 | 33 | 42 | 63 | 83 | 104 | 125 | 167 | 208 |

| Length (L) (mm) | 1700 | 21000 | 2050 | 1950 | 2370 | 2400 | 2700 | 2600 | 3050 |

| Width (W) (mm) | 1010 | 1010 | 1010 | 1210 | 1210 | 1410 | 14100 | 1610 | 1610 |

| Height (H) (mm) | 1600 | 1600 | 1680 | 1950 | 1950 | 2160 | 2160 | 2300 | 2300 |

| Weight (kg)* | 1169 | 1412 | 1637 | 2075 | 2266 | 3118 | 3227 | 40000 | 4499 |

| YS SERIES SEMI-CYLINDRICAL TYPE HOT / SUPERHEATED WATER BOILERS | YS60 | YS70 | YS80 | YS90 | YS100 | YS110 | YS120 | YS150 |

| Max. Working Pressure (bar g) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Total Heat Transfer Surface Area (m2) | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 150 |

| Max. Thermal Capacity (kW)** | 1047 | 1221 | 1395 | 1570 | 1744 | 1919 | 2093 | 2616 |

| Max. Thermal Capacity (kcal/h)** | 900.000 | 1.050.000 | 1.200.000 | 1.350.000 | 1.500.000 | 1.650.000 | 1.800.000 | 2.250.000 |

| Water Circulation Flow (m3/h)*** | 45,00 | 52,50 | 60,00 | 67,50 | 75,00 | 82,50 | 90,00 | 112,50 |

| Fuel Consumption (kg/h)** | 250 | 292 | 333 | 375 | 417 | 458 | 500 | 625 |

| Length (L) (mm) | 2650 | 2950 | 3250 | 3250 | 3430 | 3680 | 3930 | 4730 |

| Width (W) (mm) | 1810 | 1810 | 1810 | 2010 | 2010 | 2010 | 2010 | 2010 |

| Height (H) (mm) | 2700 | 2700 | 2700 | 2860 | 2860 | 2860 | 2860 | 2860 |

| Weight (kg)* | 5780 | 5479 | 5977 | 8037 | 8210 | 8360 | 8449 | 10650 |

- *For 5 bar, empty boiler body without accessories.

- ** For fuel with a lower thermal value of 4500 kcal/kg.

- *** Difference between flow and return temperatures∆T=20ofor C.

- Akkaya Inc reserves the right to make changes to the specifications.

Gallery